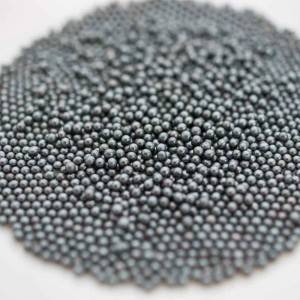

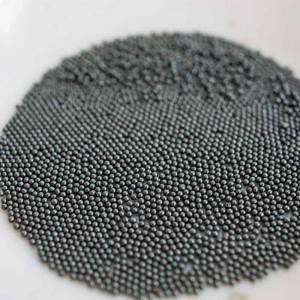

Ikhabhoni ephantsi eRounded Steel Shot

Imodeli/ubungakanani:S110-S930/Φ0.3mm-2.8mm

Iinkcukacha zeMveliso:

Izithonga zentsimbi yekhabhoni ephantsi zinekhabhoni encinci, i-phosphorus kunye nesulfure kunezithonga eziphezulu ze-carbon steel.Ke ngoko, ulwakhiwo lwangaphakathi oluncinci lwekhabhoni ephantsi luthambile kakhulu.Izithonga zentsimbi yekhabhoni ephantsi zithambile xa zithelekiswa nezidubulo zentsimbi yekhabhoni ephezulu.Oku kukhokelela kwi-20 - 40 % yexesha elide lobomi bokulimala.

IiNgcaciso eziphambili:

| IPROJEKTHI | INGCACISO | INDLELA YOVAVANYO | |||

| UHLELO LWEKHEMICAL | C | 0.08-0.2% | P | ≤0.05% | ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

|

| Si | 0.1-2.0% | Cr | / |

|

|

| Mn | 0.35-1.5% | Mo | / |

|

|

| S | ≤0.05% | Ni | / |

|

| IMICROTRUCTURE | I-Homogeneous Martensite okanye i-Bainite | GB/T 19816.5-2005 | |||

| Ukuxinana | ≥7.0-10³kg/m³(7.0kg/dm³) | GB/T 19816.4-2005 | |||

| NGAPHANDLE | Umngxuma womoya < 10%.Idibanisa.Ikona ebukhali.Ireyithi yokukhubazeka< 10% | Okubonakalayo | |||

| UBUNZIMA | I-HV:390-530(HRC39.8-51.1) | GB/T 19816.3-2005 | |||

Amanyathelo Okulungisa:

Isilaphu→Khetha&Sika→Ukunyibilikisa→Coca(decarbonize)→Ukomisa→Ukomisa→Uqwalaselo lweScalper→Ukuphefumlela nokuvuthela ukususa umngxuma womoya→Ukucima okokuqala→Ukomisa→Ukujija→Okwesibini ukufudumeza→Ukupholisa→Uvavanyo oluhle→Ukupakisha nokuGcina

Usetyenziso:

Iindawo ezisetyenziswayo eziqhelekileyo: unyango lwangaphambili lwentsimbi okanye i-cast-iron ngaphambi kokupeyinta, ukuchithwa kunye nokususwa kwe-rust, ukuchithwa.

Izinto eziluncedo:

① Ilungele ukusetyenziswa ukubonelela ngentsimbi ecocekileyo, ekhazimlisiweyo.

② Izithonga zentsimbi ephantsi zisetyenziswa kuzo zombini ii-iturbine kunye neenkqubo zokuqhushumba komoya.Izithonga zentsimbi yekhabhoni ephantsi ziqinisekisa ukunxitywa kweeblade ze-iturbine ezisezantsi.

③Umjikelo wobomi wokudutyulwa kwentsimbi yekhabhoni imalunga ne-30% ubude kunokudubula kwentsimbi yekhabhoni ephezulu.

④ Inkqubo yokuqhunyiswa kwe-shot ivelisa uthuli oluncinci, olukhokelela kwiindleko eziphantsi zokugcinwa kwenkqubo yokucoca.

Kutheni iKhabhoni iphantsi?

Ikhabhoni ephantsi kunye nentsimbi ephezulu yemanganese edutyulwe inefuthe eliphezulu lokufunxa umthamo, iimpembelelo zisasazwa ngokufanayo kulo lonke udubulo.

Ngexesha lokudutyulwa kokudubula, intsimbi ephantsi yekhabhoni ixotyulwa ibe ngamaleko abhityileyo afana neeleya zetswele ukuya kuthi ga kwi-80 yepesenti yobomi babo ngenxa yokuguga, kwaye ziqhekezwe zibe ngamaqhekeza amancinci ngenxa yokudinwa kwezinto.Ukhukuliseko lomatshini kunye ne-blade nalo luncitshiswe kakhulu njengoko lwahlulahlulwe lube ziindawo ezincinci nezincinci.

I-carbon steel shot particles ephezulu nangona kunjalo ziqhekezwe zibe ziziqwenga ezinkulu kunye ne-angular ngexesha elifutshane ngenxa yesakhiwo sokuqhekeka okwenziwe ngexesha lemveliso.Ngolu phawu, umatshini ubangela iindleko ezongezelelweyo eziphezulu kwisixhobo somoya kunye nezihluzi.