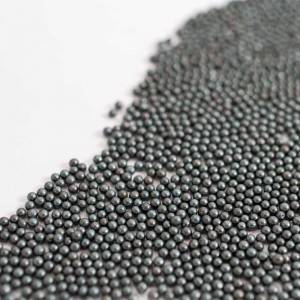

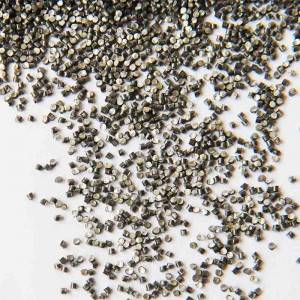

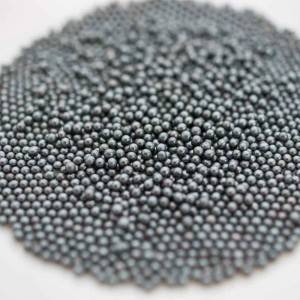

Ikhabhoni ePhakamileyo eRounded Steel Shot

Imodeli/ubungakanani:S110-S930/Φ0.3mm-2.8mm

Iinkcukacha zeMveliso:

I-carbon steel shot shot, eyenziwe ngentsimbi ekhethekileyo, ilukhuni kwaye inomsindo, inomxholo wekhabhoni omkhulu kune-0.85%. i-decarbonization, iqondo lokushisa kwinkqubo yokucima, kunye nokupheliswa kwee-pores kunye nokungaqhelekanga emva kokuqulunqwa, okuphucula imveliso kwinqanaba elitsha.

IiNgcaciso eziphambili:

| IPROJEKTHI | INGCACISO | INDLELA YOVAVANYO | |||

| UHLELO LWEKHEMICAL |

| 0.8-1.2% | P | ≤0.05% | ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

| Si | ≥0.4% | Cr | / | ||

| Mn | 0.35-1.2% | Mo | / | ||

| S | ≤0.05% | Ni | / | ||

| IMICROTRUCTURE | I-Homogeneous Martensite okanye i-Bainite | GB/T 19816.5-2005 | |||

| Ukuxinana | ≥7.0*10³kg/m³(7.0kg/dm³) | GB/T 19816.4-2005 | |||

| NGAPHANDLE | Umngxuma womoya < 10%.Idibanisa.Ikona ebukhali.Ireyithi yokukhubazeka< 10% | Okubonakalayo | |||

| UBUNZIMA | I-HV:390-530(HRC39.8-51.1) | GB/T 19816.3-2005 | |||

Amanyathelo Okulungisa:

Izinto eziluncedo:

Ikhabhoni ePhakamileyo eRounded Steel Shot isebenzisa ubuchule bokwenziwa kwemveli, esetyenziselwa ukucoca uqhushumbo kunye nokudubula ukuchama ikakhulu. Unyango lobushushu olulawulwa ngokugqibeleleyo lunika ukomelela kunye nokuxhathisa ukudinwa.

kunye nokugqiba iinxalenye zetsimbi ezifuna ukunyuka kwempahla kunye nokukhathala.Kule nkqubo, ukudubula kubhobhoza inxalenye yentsimbi, idala iidimples ezincinci kumphezulu.

I-dimples ibangela ukuxinzezeleka koxinzelelo kumphezulu wenxalenye, ukwandisa ukunyanzeliswa kwesinyithi kwiintanda, ukukhathala, kunye nokubola.I-shot peening isetyenziselwa izinto ezibalulekileyo, ezinxitywayo eziphezulu njengeegiya, i-shafts kunye nezikhumba zentsimbi kwiimveliso eziphezulu ze-aerodynamic.

Usetyenziso:

Ukudubula kwethu okuphezulu kwekhabhoni yentsimbi kusetyenziselwa izicelo ezahlukeneyo ezifana;desanding, descaling, ukucoca, shot peening njl

Ukucocwa koqhushumbisi komphezulu we-forging, iziqwenga ezifudunyeziweyo, imibhobho yentsimbi, amacandelo kunye nezakhiwo zentsimbi, ukulungiswa komphezulu phambi kokupeyintwa, ukukrolwa kweengceba zokusebenza.

Ukucoca umphezulu oqhushumbayo kwiipleyiti zentsimbi, iipleyiti zentsimbi ezibhityileyo, iialloyi ezingenayo i-ferrous, idyasi yedacromet.