-

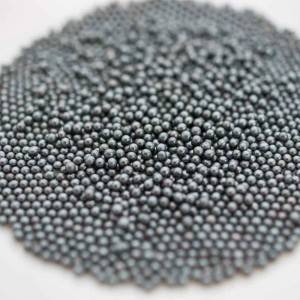

Ukuthwala i-Angular Steel Grit

Ukuthwala i-Angular Steel Grit yenziwe ngamacwecwe okuthwala amacwecwe.Intsimbi yokuthwala i-Cr, i-More elements inqabileyo, inozinzo oluhle ngaphakathi kwesakhiwo.I-Anguler steel grit inomsebenzi ozinzileyo ophezulu, ukuxhathisa ukunxiba okuphezulu, ubomi bayo bokusebenza ngamaxesha angama-2.5 ubude nje ngokuba high-carbon steel grit kunye nekhabhinethi ephantsi

-

Cast Steel Shot

I-stainless steel shot luhlobo lweendaba eziye zathandwa kakhulu.Ezi mveliso zisebenza ngokufanayo kwintsimbi yentsimbi, nangona kunjalo, zenziwe ngentsimbi engenasici.Iqulethe i-nickel ephezulu kunye ne-chromium.Kwaye imidiya elungileyo ekufuneka iqwalaselwe xa ungcoliseko lwentsimbi lomsebenzi lungenakuba

-

Stainless Steel Sika ucingo Shot

Intsimbi engenastainless cut wire shot is specialty.It yethu yenziwe SUS200, 300, 400 series steel stainless wire esikwe yangamacandelo.Intsimbi engenastainless cut wire shot isetyenziswa kwinani elandayo lezicelo ezibalulekileyo apho ungcoliseko lweferrous ekuqhunyisweni kwentsimbi engatyiwayo, titanium.

-

Ukudutyulwa kweNtsimbi eNgatyiwayo

Ukudubula kwensimbi engenasici yeForged yenziwe nge-SUS200, 300, 400 ngocingo lwentsimbi engenasici kwaye yaphantsi ibe ziibhola ezahlukeneyo ezingqukuva.

-

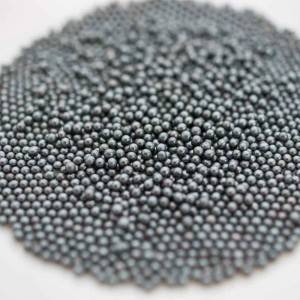

Ikhabhoni ePhakamileyo eRounded Steel Shot

I-carbon steel shot shot, eyenziwe ngentsimbi ekhethekileyo, ilukhuni kwaye inomsindo, inomxholo wekhabhoni omkhulu kune-0.85%. decarboniza

-

Ikhabhoni ephantsi eRounded Steel Shot

Izithonga zentsimbi yekhabhoni ephantsi zinekhabhoni encinci, i-phosphorus kunye nesulfure kunezithonga eziphezulu ze-carbon steel.Ke ngoko, ulwakhiwo lwangaphakathi oluncinci lwekhabhoni ephantsi luthambile kakhulu.Izithonga zentsimbi yekhabhoni ephantsi zithambile xa zithelekiswa nezidubulo zentsimbi yekhabhoni ephezulu.

-

Ukudubula kweAluminiyam/ukusika ucingo

I-Aluminium cut-wire shot (i-Aluminium Shot) ifumaneka kumabakala axubileyo e-aluminium (4043, 5053) kunye namabakala e-alloy afana nohlobo lwe-5356. Amanqaku ethu axubileyo avelisa uluhlu oluphakathi lwe-B (malunga nama-40) ukuqina kwe-Rockwell ngelixa uhlobo lwe-5356 luya kunika i-Rockwell ephezulu. B ubunzima kuluhlu lwama-50 ukuya kuma-70.

-

Red Copper shot / ubhedu cut wire shot

1. Isusa ifleshi ukuya kuthi ga kwi-0.20 ″ kwi-die castings ngaphandle kokonakalisa umphezulu

Yehlisa ukunxiba kunye nokukrazula kwisixhobo sokuqhushumba

Isusa ipeyinti kunye nezinye iingubo ngaphandle kokonakalisa umphezulu wenxalenye

Ifilimu encinci ye-zinc ifakwe kwiindawo zentsimbi ngexesha lomjikelo wokubonelela ngokhuseleko lwexesha elifutshane -

Zinc shot/Zinc cut wire shot

Sinikezela ngoluhlu olusemgangathweni lweZinc Cut Wire Shots.Ifumaneka kumazinga afanelekileyo, iimveliso zethu zinciphisa ukuguga kunye nokukrazula kwisixhobo sokuqhushumba.Ezi zithonga zocingo ezisikiweyo zeZinc zithambile kunocingo olusikiweyo lwentsimbi engatyiwayo okanye iimveliso eziphosiweyo.I-Zinc cut wire shot ifumaneka ngobukhulu obahlukeneyo.

-

UkuSila iSteel Shot

I-alloy yokusila intsimbi isekelwe kukudubula kwentsimbi yekhabhoni ephezulu, ukudutyulwa kwentsimbi ephantsi kwekhabhoni, kunye nokudutyulwa kwentsimbi ephantsi ye-vanadium, kuthathelwa ingqalelo ubuthathaka obubulalayo bezi mveliso zingasentla: umngxuma womoya, iintanda, umahluko wobulukhuni, phuhlisa iimveliso ezintsha ngokuphinda zisetyenziswe. itekhnoloji yokubumba, inokukhetha izinto ezahlukeneyo

-

Ukuqulunqa ibhola yentsimbi

Ukwenziwa kwebhola yentsimbi eyenziwe ngentsimbi engqukuva njengesixhobo ekrwada, ecutshungulwa ngokwasemzimbeni ngobuchule obutsha bokuqengqeleka kunye nokubunjwa ize iveliswe bubuchwephesha obukhethekileyo bonyango lobushushu.

Emva kweminyaka yokuqokelela kunye novavanyo oluphindaphindiweyo, -

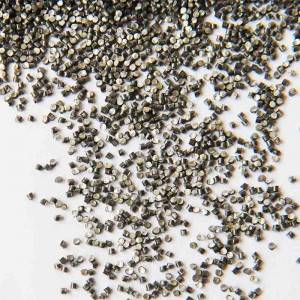

Sika i-wire Shot / ucingo olutsha

I-Cut Wire Shot yenziwe ngocingo oluphezulu olusikwe ukuya kubude obulingana nobubanzi balo.Ucingo olusetyenziselwa ukuvelisa i-Cut Wire Shot ingenziwa ngeCarbon Steel, i-Stainless Steel, i-Aluminium, i-Zinc, i-Nickel Alloy, i-Copper okanye ezinye i-alloys zetsimbi.Isenayo iikona ezibukhali ukusuka ekusikeni

-

Sika ucingo lokudutshulwa / ucingo olusetyenzisiweyo

Ukudutyulwa kwentsimbi ehlaziyiweyo luhlobo lwemveliso esebenzisa imathiriyeli esetyenzisiweyo, ixabiso layo lezinto eziphathekayo liphantsi, kwaye kunzima ukuvelisa iimveliso ezichanekileyo, olu hlobo lwemveliso lunokusetyenziswa kuphela ukucoca umphezulu owenziwe ngokutsha. iindawo.Kubathengi abangenayo ekhethekileyo

-

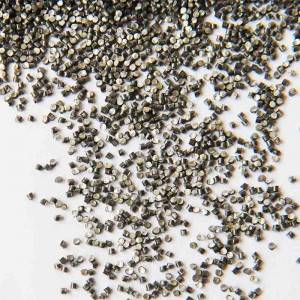

Igrithi yentsimbi yeCarbon ephezulu yeAngular

Igrit yentsimbi yekhabhoni ephezulu ye-angular yenziwe kwikhabhoni ephezulu yokudutyulwa kwentsimbi.Izithonga zentsimbi ezityunyuziweyo zibe yigranular grit form kwaye emva koko zithotywe zibe ziinzima ezintathu ezahlukeneyo (GH, GL kunye neGP) ukulungiselela izicelo ezahlukeneyo.Igrit yentsimbi ephezulu yekhabhoni isetyenziswa ngokubanzi njengesixhobo sokusasaza i-descali

-

I-Carbon ephantsi ye-Angular Steel Grit

Igrit ephantsi ye-carbon angular steel grit yenziwe ngentsimbi ephantsi yekhabhoni

shot.Izithonga zentsimbi ezityunyuziweyo zibe yigranular grit.Azinaziphene ngenxa yonyango lobushushu ekubeni unyango olongezelelweyo aluyomfuneko.

- Umnxeba

- 0086-632-5985228

- I-imeyile

- info@fengerda.com