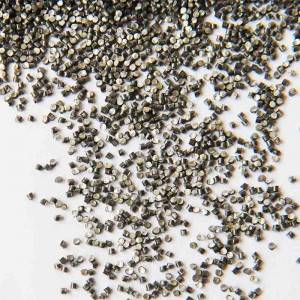

I-Carbon ephantsi ye-Angular Steel Grit

IiNgcaciso eziphambili:

| IPROJEKTHI | INGCACISO | INDLELA YOVAVANYO | |||

| UHLELO LWEKHEMICAL | C | 0.08-0.2% | P | ≤0.05% | ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

|

| Si | 0.1-2.0% | Cr | / |

|

|

| Mn | 0.35-1.5% | Mo | / |

|

|

| S | ≤0.05% | Ni | / |

|

| IMICROTRUCTURE | I-Homogeneous Martensite okanye i-Bainite | GB/T 19816.5-2005 | |||

| Ukuxinana | ≥7.0-10³kg/m³(7.0kg/dm³) | GB/T 19816.4-2005 | |||

| NGAPHANDLE | Iprofayile yomphezulu echongiweyo okanye i-angular, Umngxuma womoya < 10%. | Okubonakalayo | |||

| UBUNZIMA | I-HV:390-530(HRC39.8-51.1) | GB/T 19816.3-2005 | |||

Amanyathelo Okulungisa:

Isilaphu→Khetha&Sika→Ukunyibilikisa→Coca(decarbonize)→Ukomisa→Ukomisa→Uqwalaselo lweScalper→Ukuphefumlela nokuvuthela ukususa umngxuma womoya→Ukucima okokuqala→Ukomisa→Ukujija→Okwesibini ukufudumeza→Ukupholisa→Ukwaphulwa→Uvavanyo oluhle→Ukupakisha nokuGcina

IINDLEKO ZOKUXHUMANA KWENKQUBO YENKANTSI EPHANSI

• Ukusebenza ngaphezulu kwe-20% ngokuchasene nokudutyulwa kwekhabhoni ephezulu

• Ukuthotywa kancinci koomatshini kunye nezixhobo ngenxa yokufunxeka okukhulu kwamandla kwiimpembelelo kwiziqwenga.

• Amalungu angenaziphene aveliswa lunyango lwe-thermal, iifractures okanye ii-micro cracks

UKUPHUCULA EZENDALO

• Ukunciphisa umgubo

• I-Bainitic microstructure iqinisekisa ukuba ayiyi kuphuka ngexesha lokuphila kwayo

INKCAZELO NGOKUBANZI

Ubume bokudubula kwentsimbi yekhabhoni ephantsi kuyafana nengqukuva.Ubukho obuncinci beengqungquthela ezide, ezinokukhubazeka kunye neepores, i-slag okanye ukungcola kunokwenzeka.

Oku akuchaphazeli ukusebenza kokudubula, kunokuqinisekiswa ngokulinganisa ukusebenza kwayo kumatshini.

UBUNZIMA

I-bainitic microstructure iqinisekisa iqondo eliphezulu lobunzima.I-90% yamasuntswana aphakathi kwe-40 - 50 ye-Rockwell C.

Ikhabhoni ephantsi yokulinganisela kunye ne-manganese iqinisekisa ubomi obude obuncedo beengqungquthela, ngaloo ndlela iphucula ukucoceka kweengcezu, ekubeni ngomsebenzi womatshini bandisa ubunzima babo.

Amandla okudutyulwa kokudubula afunxwa ikakhulu ngamalungu, ngaloo ndlela kunciphisa ukunxiba komatshini.

UKUBEKA KHABHONA, UKUSEBENZA OKUPHEZULU

Ukusetyenziswa kwekhabhoni yentsimbi ephantsi kunomda koomatshini abanee-turbines ze-2500 ukuya kwi-3000 RPM kunye nesantya se-80 M / S.

Kwizixhobo ezitsha ezisebenzisa i-3600 RPM turbines kunye nesantya se-110 M / S, ezi ziyimfuneko zokwandisa imveliso.